Products

Product Categories

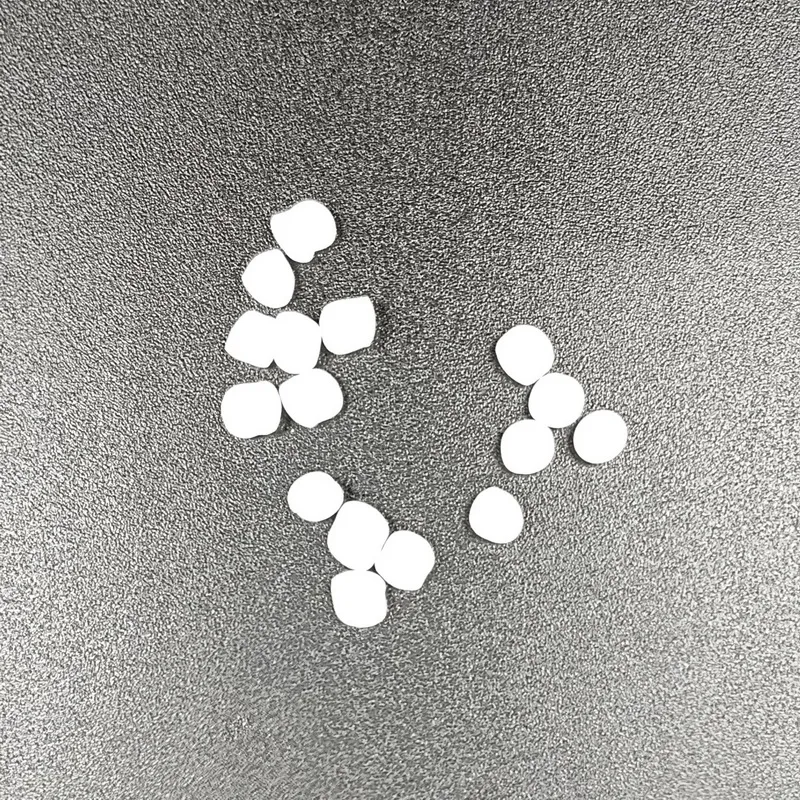

HDPE non virgins

HDPE is the acronym for High Density Polyethylene (High Density PolyEthylene), which is a thermoplastic prepared from ethylene through a catalytic process.

Product Description

What are the properties of HDPE ?

(1)High tensile strength (the maximum stress the material can withstand)

(2)Density higher than 0.95–0.97 g/cm3 (floating in water)

(3)High heat resistance (maximum temperature approx. 120°C)

(4)Excellent chemical and solvent resistance

(5)high rigidity

(6)Compliant with FDA’s standard for direct food contact

What is HDPE mainly used for?

More than 8 million tons of HDPE are used to blow mold containers such as milk jugs, juice containers, detergent bottles, motor oil bottles, trash cans, etc. This is almost one-third of the annual global HDPE production.

Most recycled HDPE plastic is made into composite lumber or plastic lumber.

One-third of the toys are made of high-density polyethylene.

Some bottle makers are able to combine recycled PET and HDPE plastics, which are available through PCR-style recycling schemes. The plastic is washed and turned into pellets before being reprocessed into food-safe, FDA-approved plastic bottles.

What is the difference between HDPE and PE?

HDPE: High Density Polyethylene

LDPE: Low Density Polyethylene

LLDPE: Linear Low Density Polyethylene

PE = Polyethylene, polyethylene, is the simplest polymer organic compound

1. Different in nature

1. HDPE: It is high-density polyethylene, which is a white powder or granular product.

2. PE: It is polyethylene, a thermoplastic resin obtained by polymerization of ethylene.

Two, different characteristics

1. HDPE: non-toxic, odorless, crystallinity of 80%-90%, softening point of 125-135°C, service temperature up to 100°C; hardness, tensile strength and creep are better than low-density polyethylene; Good wear resistance, electrical insulation, toughness and cold resistance; at room temperature, it is insoluble in any organic solvent, and resistant to acid, alkali and various salts.

2. PE: It feels like wax, has excellent low temperature resistance, good chemical stability, and can withstand most acid and alkali erosion (not resistant to acids with oxidizing properties). Insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation.

3. Different applications

1. HDPE: Plastic products can be formed by injection, extrusion, blow molding and rotational molding. Various types of containers, industrial accessories, medical supplies, toys, shells, bottle stoppers and shields can be formed by injection molding. Blow molding can be used to form various hollow containers, ultra-thin films, etc.

2. PE: More than half of it is used for film products, followed by pipes, injection molding products, wire wrapping layers, etc.; medium and low pressure polyethylene, mainly injection molding products and hollow products; ultra-high pressure polyethylene: due to ultra-high molecular weight Polyethylene has excellent comprehensive properties and can be used as engineering plastics.