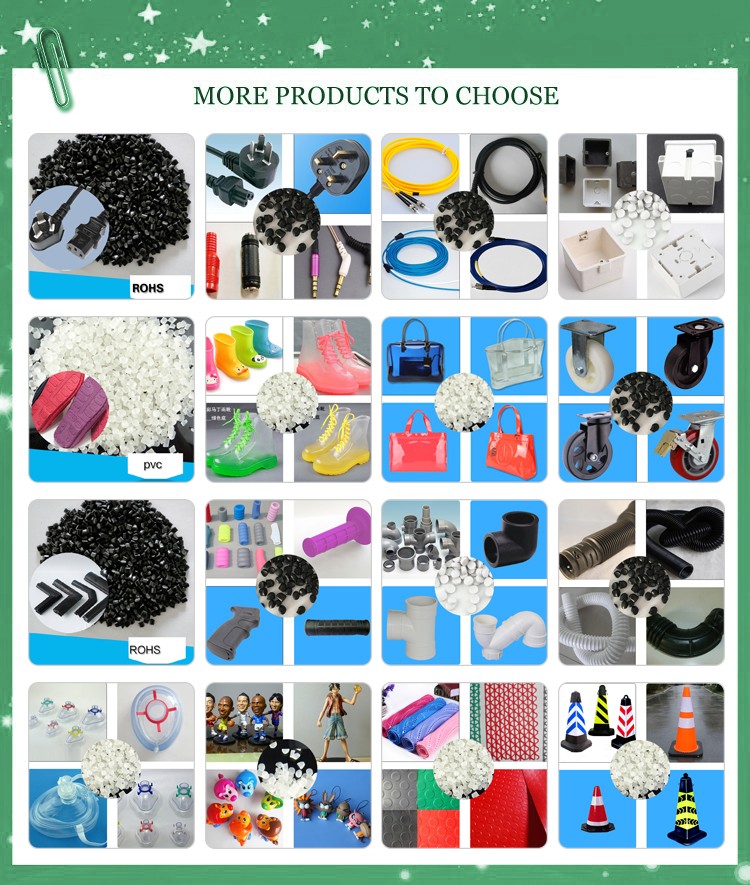

Products

Product Categories

PVC Plastic For Kids Children Boots Injection

- Material:100% Virgin Compounds

- Hardness:ShoreA50-65

- Density:1.18-1.25g/cm³

- Application:Children Boots Upper& Soles

Product Description

INPVC offer 100% new PVC compounds used for Kids Children Boots production. Our footwear compounds with high mechanical resistance, efficiency in processing, innovation and superior appearance. We supply customized & special formulation as per requirement with assurance of quality and services.

Economical, versatile polyvinyl chloride (PVC, or vinyl) is best known as the plastic material that makes clear, colorful, light-up rain boots.

Our material’s ingredients are Non-toxic, completely and naturally in step with our health and safety policy. All components are in accordance with the EU ROHS environmental directives, regarding the prohibition of using harmful substances such as Nickel, Lead and Cadmium.

INPVC’s compound is made from special and selected ingredients to achieve the specific properties which mark the kids boots: extremely lightness, softness and flexibility even at low temperatures, high resistance to acids, manure, fertilisers and sprays, long-term durability.

Dongguan Humstar Macromolecule Technology Co., Ltd. is a R & D, production and sales integration of environmentally friendly PVC plastic raw material.We has passed ISO9001:2008 quality management system certification of well-known enterprises. We also passed several environmental certifications, such as ROHS,PAHS,REACH,SGS .And satisfied the standard of toy and medical industries.The company is committed to creating a professional environment-friendly PVC plastic raw materials integrated production plant.The company has factories, office buildings and dormitories 15000 square meters. Since its established, we introduce a full set of international advanced level of production equipment, with a dust-free workshop specializing in the production of medical grade, food grade and other high-end PVC rubber. Factory equipped with laboratory, can provide professional proofing, color, weight, hardness, environmental protection test services. Production workshop with 12 sets 150mm synchronous twin screw extruder, 5 sets 120mm single screw extruder, and equipped with sophisticated detection equipment.Our comprehensive monthly production capacity reached 1000 tons. We has professional and technical and production management personnel more than 50 people, to provide customers with high quality products and perfect after-sales service. The company has consistently adhered to the “people-oriented, innovative development, harmonious coexistence” business philosophy, and constantly enhance market competitiveness, to meet customer demand for quality and service.We can supply PVC material: high transparent PVC, food grade PVC, medical PVC, tasteless PVC, toy PVC, cable&wire PVC, furniture PVC , articles for daily use PVC granules and anti-static sole PVC particles etc..The products are mainly used in rubber materials with various specifications of PVC toys, furniture,plug,bathroom,medical,electronic wire&cable series products and a variety of PVC injection molding products and so on. According to the actual need of the required products of customers, we can design and develop the products such as SR, heat, cold, water and oil resistant, high fuel resistance, anti-static, special environmental protection, the national environmental protection requirements and so on.

In order to fight against the new coronavirus, our factory has introduced advanced equipment and engineers this year, equipped with a new MFI-1500 PP particle production line, specializing in the production of mask melt blown PP particles and electret masterbatch.

“Gold quality, Top brand, Win world” are our pursuit and goal, With more than ten years’ experience, we will renew the management concept and equip with advanced technology to meet the demand of customers at home and abroad.we warmly welcome you to cooperate with us.