TPE and TPR definitely offer some differences, which really comes down to their base materials. TPE is modified from SEBS base material and TPR is often modified from SBS.

To better understand the difference in the manufacturing processes behind TPE and TPR, we must first break down the meaning of SEBS base material and SBS.

What are SEBS and SBS?

Styrene Ethylene Butylene Styrene Block Copolymer (SEBS) is the product of hydrogenated SBS. But what exactly is SBS? It’s styrene-butadiene-styrene block copolymer, which offers soft-touch characteristics utilised extensively by designers – especially in hand tools.

What does this mean in relation to SEBS? It’s the act of introducing molecular hydrogen to unsaturated molecules in special reaction conditions. What this does is ensure the molecular structure becomes saturated, which offers anti-aging properties, as well as resistance to yellowing. On top of this, it also ensures higher heat and corrosion resistance than SBS, therefore resulting in a higher performance output of TPE over TPR.

TPE choices

There’s a lot to choose from, with TPE groups available, including:

Polyolefin blends (TPE-O)

Styrenic block copolymers (TPE-S)

Elastomeric alloys

Thermoplastic polyurethanes (TPE-U)

Thermoplastic polyamides (TPE-A)

Thermoplastic co-polyesters (TPE-E)

With the flexibility of plastics and rubber, both TPE and TPR are used widely in engineering, but for different applications. In TPR, specifically, its unsaturated molecular structure is similar to that of rubber, which gives it its elastic feel.

The Shore durometer scale

TPEs are certainly thermoplastic, but they still offer similar elasticity to their cross-linked rubber counterpart. This is determined by its softness or hardness, which is monitored on a scale known as the Shore durometer.

Available as soft gel materials – from 20 Shore OO up to 90 Shore AA – TPEs possess similar qualities to crosslinked rubber. After reaching 90 Shore AA, they are introduced to the Shore D scale, which means they can be formulated to achieve a hardness of up to 85 Shore D.

TPRs are available in a wide range of durometers, from 20 Shore OO to 85 Shore D – again, this aligns with TPE.

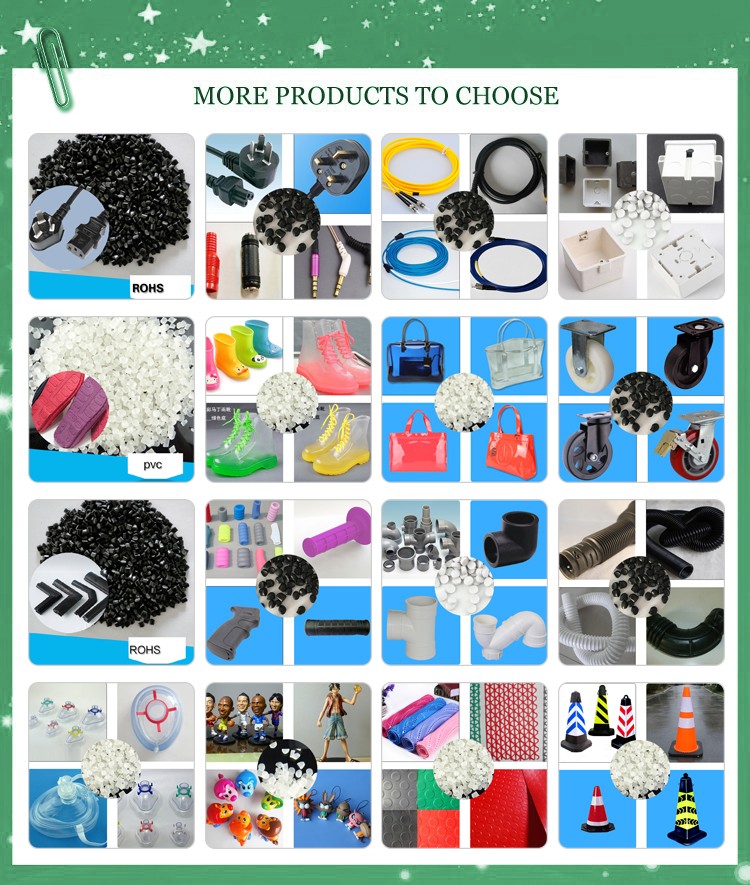

Dongguan Humstar Macromolecule Technology Co., Ltd. is a R & D, production and sales integration of environmentally friendly PVC plastic raw material.We has passed ISO9001:2008 quality management system certification of well-known enterprises. We also passed several environmental certifications, such as ROHS,PAHS,REACH,SGS .And satisfied the standard of toy and medical industries.The company is committed to creating a professional environment-friendly PVC plastic raw materials integrated production plant.The company has factories, office buildings and dormitories 15000 square meters. Since its established, we introduce a full set of international advanced level of production equipment, with a dust-free workshop specializing in the production of medical grade, food grade and other high-end PVC rubber. Factory equipped with laboratory, can provide professional proofing, color, weight, hardness, environmental protection test services. Production workshop with 12 sets 150mm synchronous twin screw extruder, 5 sets 120mm single screw extruder, and equipped with sophisticated detection equipment.Our comprehensive monthly production capacity reached 1000 tons. We has professional and technical and production management personnel more than 50 people, to provide customers with high quality products and perfect after-sales service. The company has consistently adhered to the “people-oriented, innovative development, harmonious coexistence” business philosophy, and constantly enhance market competitiveness, to meet customer demand for quality and service.We can supply PVC material: high transparent PVC, food grade PVC, medical PVC, tasteless PVC, toy PVC, cable&wire PVC, furniture PVC , articles for daily use PVC granules and anti-static sole PVC particles etc..The products are mainly used in rubber materials with various specifications of PVC toys, furniture,plug,bathroom,medical,electronic wire&cable series products and a variety of PVC injection molding products and so on. According to the actual need of the required products of customers, we can design and develop the products such as SR, heat, cold, water and oil resistant, high fuel resistance, anti-static, special environmental protection, the national environmental protection requirements and so on.

In order to fight against the new coronavirus, our factory has introduced advanced equipment and engineers this year, equipped with a new MFI-1500 PP particle production line, specializing in the production of mask melt blown PP particles and electret masterbatch.

“Gold quality, Top brand, Win world” are our pursuit and goal, With more than ten years’ experience, we will renew the management concept and equip with advanced technology to meet the demand of customers at home and abroad.we warmly welcome you to cooperate with us.

Tel:0086 769 82550680

Fax:0086 769 89363776

Cell phone:0086 18688639880

Email: plasticcenter05@cn-humstar.com

WhatsApp: +86 13925545836(Wechat)

Address:No.1 Jiujiangshui Luduan,Dongshen Road,Changping Town,Dongguan City,Guangdong Province,China.